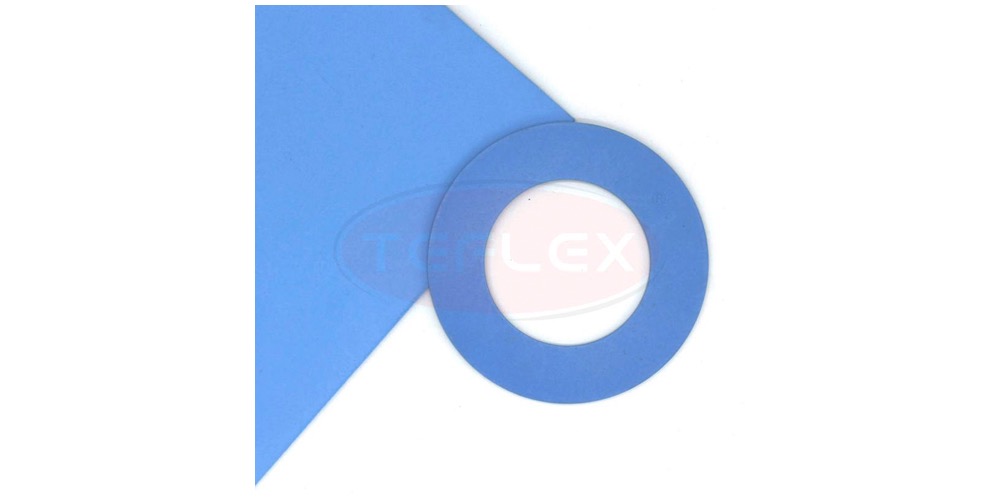

Most industrial operations involve several components. Some of the operations require gaskets. Gaskets available in the market are made of different materials. The most commonly used material is Teflon, which is also known as PTFE. You can also check Teflex Glass Microspheres Filled PTFE Sealing and how to use it. This type of gasket is widely used due to its chemical and physical properties. They can also be modified and used in place of sealants.

You should note that Teflon is a synthetic polymer that has excellent corrosion resistance and minimal friction. Other important features include high resilience, high surface wear, and high operational temperature. That explains why this gasket is ideal for different applications. Usually, manufacturers combine these gaskets with certain materials to increase their performance in certain applications. Another reason you should start using a PTFE gasket is its long lifespan. With this product, you can reduce maintenance costs. These are some of the areas where Teflon gaskets are used.

Oil and Gas Industry

For many years, Teflon gaskets have been used to handle petrochemicals and chemicals because of their excellent resistance to corrosive substances. Also, they can withstand extremely high temperatures. However, they cannot be used in an area with fluorine substances and some alkali materials. This gasket offers adequate resistance to PTFE at different temperatures and pressures. Moreover, it is suitable in areas where hydraulic fluids are likely to come into contact with the sealing.

Medical Equipment

It is vital to note that Teflon is widely used in the medical and pharmaceutical industries. For instance, you can find PTFE sealants in implantable tools. The good thing about this material is that it helps withstand damage that is caused by different manufacturing processes. The temperature and chemical resistance of Teflon means that medical equipment manufacturers have the required sealants for different applications. Remember that gaskets help prevent mix-up or contamination of medical products.

Electrical Components

The truth is that the PTFE gasket is ideal for various electrical components that include electric motors, transformers, and different electrical appliances. Remember that the PTFE sealant is designed to remain unchanged in chemical environments and temperatures. Surface wear and corrosion resistance are the main purposes you should embrace these types of gaskets.

Food Processing Industry

The main reason PTFE is used in the food processing industry is that it is considered to be a food-grade material. Thus, it can be used in processing equipment for medical and food products. You should note that Teflon has a strong atomic structure. As a result, it does not react with other materials. Also, its excellent chemical resistance ensures foods being processed cannot be contaminated with the sealant.

Some of the manufacturing techniques used to make PTFE gaskets are die cutting and waterjet cutting. The good thing about die-cutting is that it can make high precision, complex gaskets. Also, higher cutting speeds ensure quick delivery of parts and products.

On the other hand, waterjet cutting provides accurate positioning to ensure repeatability. The CNC-controlled waterjet is accurate. Also, the method ensures that tight tolerances can be achieved. When choosing a gasket, ensure you consider the application and whether it will meet the standard requirements.