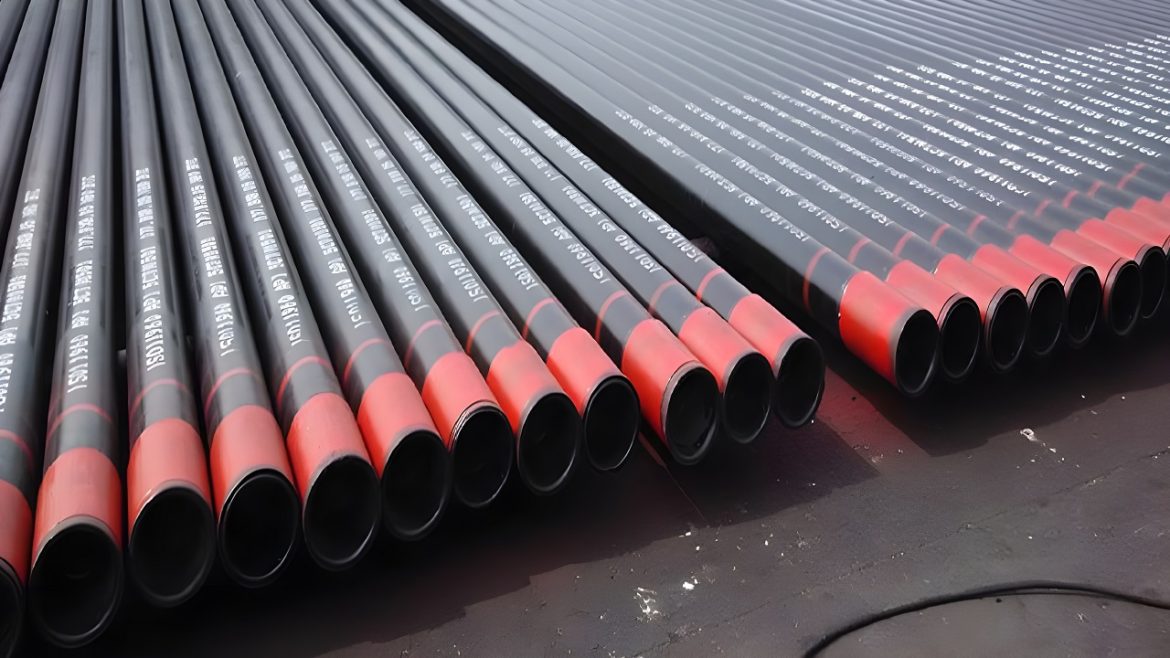

The integrity and longevity of casing pipes are crucial in the oil and gas industry. The mechanical strength and performance characteristics of API 5CT J55 OCTG have made it a popular choice as a petroleum casing pipe material. The mechanical strength analysis of API 5CT J55 casing pipes is the focus of this article, in which we also discuss their makeup, properties, and value to the oil and gas industry.

Understanding API 5CT J55 Casing Pipe

API 5CT J55 is a grade of casing pipe specified by the American Petroleum Institute. This grade of pipe was specifically developed to meet the stringent requirements of the oil and gas sector. Casing pipes are an essential part of any well because they prevent the wellbore from collapsing and act as a path for the removal of well fluids.

Chemical Composition

API 5CT J55’s mechanical strength is largely determined by its chemical composition. While the exact makeup may change, J55 always has a low carbon content, making it easy to weld and machine. Its mechanical properties are enhanced by the addition of manganese, copper, and sulphur in precisely controlled quantities.

Mechanical Properties

Inherent properties and meticulous production give API 5CT J55 casing pipes their mechanical strength. This grade’s high yield strength makes it suitable for use under extreme conditions. Installing and using J55 with confidence is made possible by the material’s high yield strength, which is defined as the stress at which plastic deformation begins.

Tensile Strength and Toughness

One more essential mechanical quality is tensile strength. The tensile strength of API 5CT J55 casing pipes is exceptional. Tensile strength is the maximum stress that a material can withstand before breaking. This quality is crucial for making sure the pipes can withstand the pressures and stresses incurred during drilling, installation, and use.

Impact Resistance

Casing pipes are frequently put in dangerous situations in the oil and gas industry, such as being vulnerable to impacts. Impact testing is performed on API 5CT J55 to evaluate the material’s toughness under pressure. Maintaining the well’s integrity in the face of uncertainty calls for a material with this quality.

Applications

The petroleum industry makes use of API 5CT J55 casing pipes in a wide variety of well configurations. J55 is a well-liked option for oil and natural gas wells due to its well-rounded mechanical properties. Because of its low cost and high efficiency, it is frequently chosen by well operators.

Importance to the Economy and the Environment

API 5CT J55 casing pipes’ mechanical strength affects more than just operational safety; it also has ramifications for the economy and the environment. Casing pipes that are less prone to breaking during drilling will save time and money in the long run. In addition, their durability improves sustainability over the long run by lowering the frequency with which they must be replaced, which in turn lowers resource demands.

Conclusion

The API 5CT J55 casing pipes are a perfect example of how well material science, engineering, and market needs can work together. Mechanical strength, including yield and tensile strength, impact resistance, and toughness, highlights their fitness for oil and gas extraction’s harsh conditions. These mechanical features will remain crucial for ensuring the safety and effectiveness of good operations as the energy industry develops further, leading to long-term expansion and new developments.