If we go to Wikipedia we will see that rapid prototyping is described as a set of methods used to rapidly construct a physical part or assembly with the help of three-dimensional CAD (computer aided design) data.

If you are not an engineer or haven’t been exposed to product production this might sound a bit technical, bit over the top, and to some degree intimidating.

But, even if you don’t know anything about rapid prototyping or product development, yet you have this idea in your head, you shouldn’t be deterred by that.

Here’s why!

Rapid prototyping is the straightest path to validating an idea.

In the past, just making a prototype included working with designers, developers, manufacturers, managers, and many other interested parties. Then there were the investors that you needed to convince to fund your big idea because prototyping was a really expensive process.

However, that’s not the case anymore as the process has evolved into something better, faster, and more efficient. Welcome to the exciting world of rapid prototyping.

Thanks to rapid prototyping many startups have managed to build their prototypes and MVP products without pulling big money from investors and outside funds. It won’t be an overstatement to say that they’ve built their success on the products that came directly out of their rapid prototyping efforts.

Their big secret is rapid prototyping companies!

Companies such as 3erp are the ones they are making the difference. Here’s why they are key to getting that idea from your head and turning it into a real, physical product.

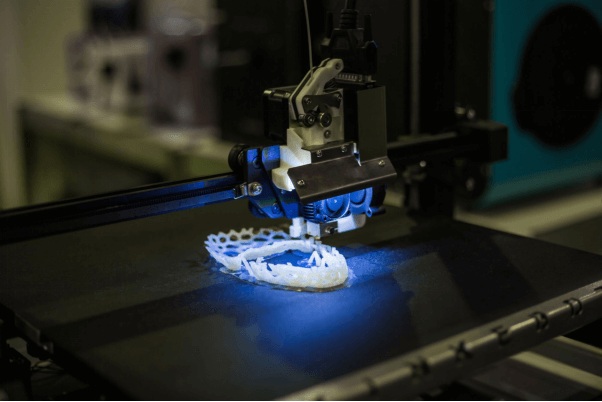

Access to various manufacturing technologies

They have everything that it takes to build your product/part. By having it all we mean manufacturing machines such as 3D printers, CNC machines, vacuum machines, injection molding machines, metal casting machines, and pretty much anything in between.

All that is in-house and can be used to create your product no matter its size, complexity, as well the material.

Access to know-how

Those companies not only have the machines but also can offer the services of experienced engineers and designers. Everyone that has ever been involved in creating a prototype knows the value of experience in the process.

Affordable rates

How much they will charge you for their services can depend on many factors such as the complexity of the part, the used materials, human labor, and so on. Sometimes the cost will equal your last year’s summer vacation, while other times can go well beyond that.

But, for a fairly simple prototype, the rate matches the cost of a used vehicle.

Fast production

Another great trait of the companies that deal with rapid prototyping is that they are very efficient in what they do. They are structured so that they can serve as many clients as possible, in the shortest possible time, while at the same time following the same high standards.

In the past, you needed to wait for months for your prototype to be made. Nowadays, that’s a matter of a month, a week, or sometimes days.

Communication

One of the most underrated aspects of creating a prototype is communication. In the early stage, in most cases, you will communicate daily with the development team. The better your communication, the easier for them will be to consult with you about some peculiarities about your prototype, or maybe if you want to make some changes. Thanks to the internet, it’s easy to get in touch and go through everything without being physically present in their facilities.

An idea is worth nothing if it lives only in your head. If you truly believe in it, then put it on paper and make something out of it. Everything else is excuses and fear of failure. As the great Wayne Gretzky once said: “You miss 100% of the shots you don’t take”.