How to Maximize Efficiency With Your Blow Molding Machine

Greetings, folks! It s incredible to have you her [ ]

Greetings, folks! It s incredible to have you her [ ]

Fiber optics has become necessary in the information er [ ]

Hello, my friends! Thanks for joining us on this deep-d [ ]

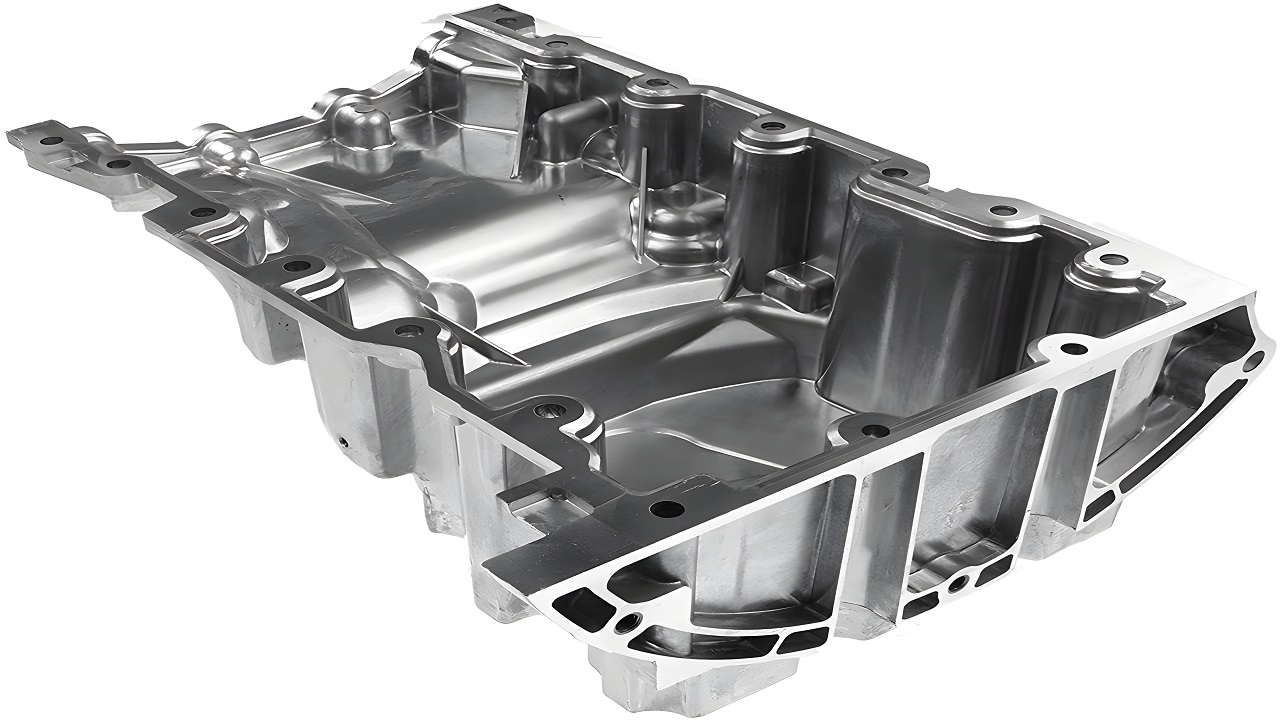

In the intricate realm of automotive engineering, certa [ ]

According to the technical delivery requirements specif [ ]

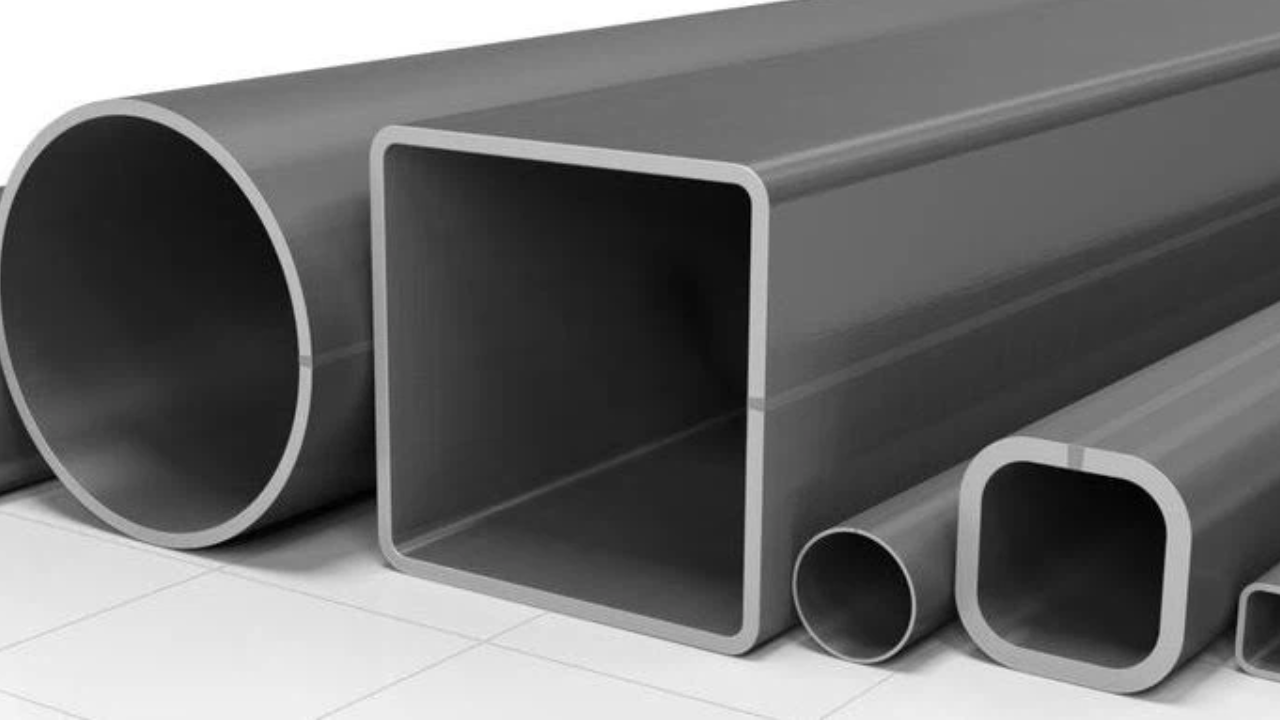

There are numerous different parts required for a syste [ ]

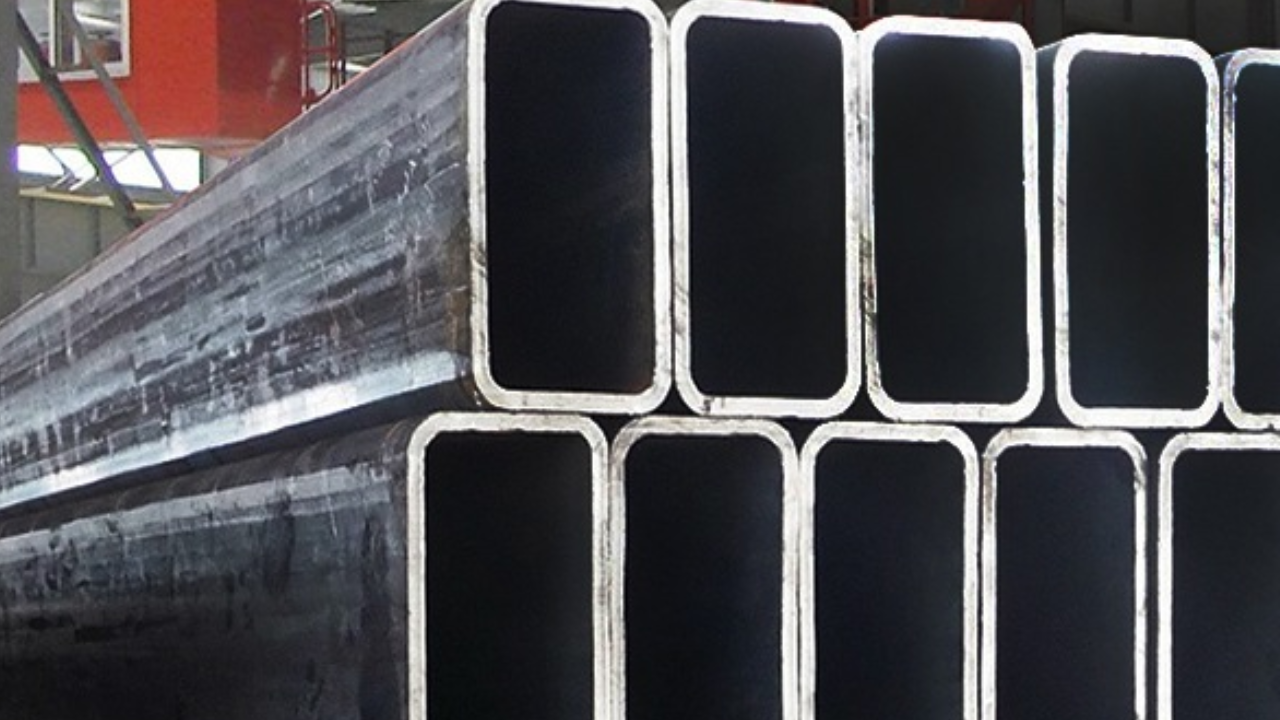

For Electric Resistance Welded (ERW) steel pipes that t [ ]

An essential part of fire safety in buildings and struc [ ]

AS1163 is the Australian/New Zealand Standard for hollo [ ]

In the realm of modern engineering, the ability to tail [ ]