The healthcare sector is still experiencing dramatic changes since the outset of technology in the world. Today, there is a major focus on public policies and their applications to the well-being of patients. The sector continues to undergo radical process changes in product creation and delivery. That is where the introduction of CNC machining comes in too.

1. CNC Machining: Towards Milestones in the Healthcare Sector

Because of its precision, material versatility, and speed, CNC machining China processes are crucial to the medical industry’s efficiency. From bedside monitoring devices to implants, different machined parts are always found in the healthcare sector.

Several medical parts and machines are manufactured using CNC machines in China. These CNC Machines are capable of making various parts with tight and high tolerances. The focus has always been on producing bio-safe materials that can be used in the long run to better the health industry.

Over and above, CNC machining process needs to be capable of manufacturing parts that can easily meet international and governmental standards, including the ones set by the FDA.

2. Making implants

One major use of the medical CNC machining China is producing various bodily implants like knee implants coupled with hip replacements. Patient-tailored implants are known to be suitable for their short turn-around times, little to no tooling costs, and availability. This should make the process ideal for one-off and tailor-made parts as opposed to the common mass-produced parts.

The implants can be machined from various metals such as titanium or plastic such as PEEK. The elements do not just need to be sturdy but durable too. They should also be relatively compatible. Besides, being medical equipment, they should not corrode because they would break into the human body, thus causing a risk to a patient’s health.

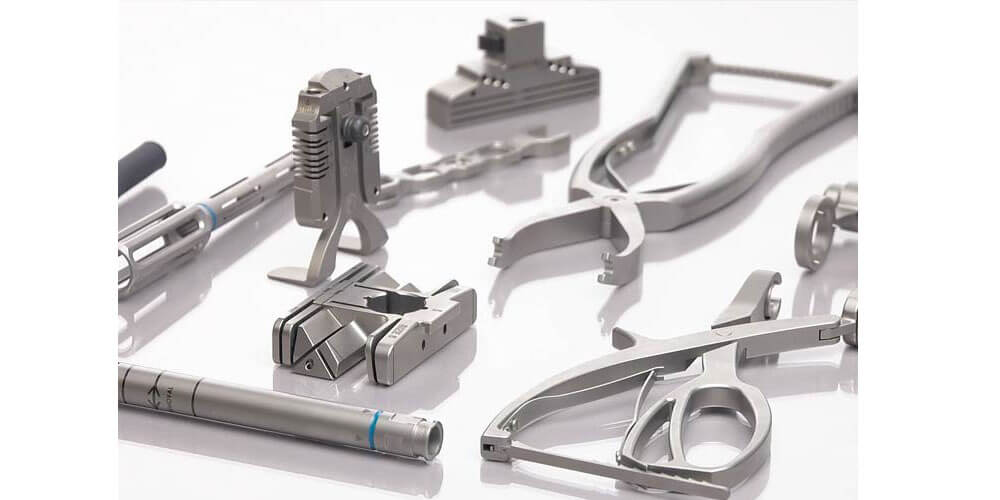

3. Making machined surgical parts

Besides creating bodily implants, a CNC machining process can also be used to manufacture surgical instruments. Various medical professionals often use these instruments at the operating table. The metal components can include biopsy tubes, cutters, implant holders, spacers, and plate benders.

The CNC surgical tools have to be made with precision. They must also be subjected to safety requirements that guarantee sterilization. Manufacturers of medical devices often favor CNC machining methods for surgical tools, given that there is a demand for precision tools in the medical sector. Some can be fabricated for a few patients depending on their prognosis.

4. Micromachining

The medicine industry is gigantic. However, device manufacturers should make small parts if the healthcare practitioners are to be successful in tailoring treatment. There is a standard requirement for implantable devices and exploratory tools. That is where micromachining, which is directly related to CNC machining, comes in. The practice can also be used to help produce catheters, drug delivery systems, miniature screws designed for implants, in addition to other devices.

Final Thoughts

Every machine shop that can provide precision machining should have the recommended resources to manufacture medical parts. Given the sensitivity of patient’s health, the manufacturer of such machines needs to deliver top-notch quality products.