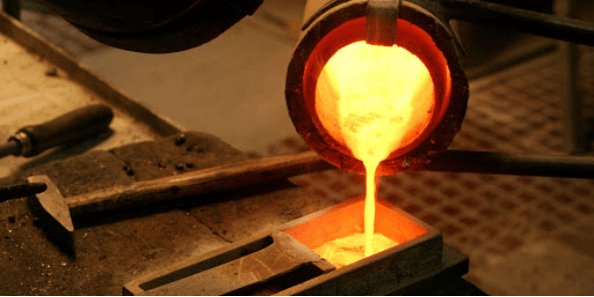

In a time of crisis like the current pandemic, people like to open topics such as the significance of metal casting, is it that important, or is it an overhyped industry?

Well, here comes a combination of facts and arguments that explain precisely that, the significance of metal casting.

To make things easier to follow, we’ve made our case through a list of top five arguments on why metal casting is so important and will remain such in the foreseeable future.

#1 Metal Casting is Essential to Almost Every Industry

Some industries that rely most on metal casting are mining, transportation, health care, railroad, construction, automotive, defense, energy sector, water infrastructure, aerospace, and agriculture. In simple terms, modern society depends on metal casting and products that come out of it.

The list of cast metal parts is also quite extensive. But once again, to put things in better perspective, the list of cast metal parts include:

- Manhole covers

- Engine blocks

- Pumps

- Flowmeter housings

- Turbine housings

- Drainage grates

- Fire hydrants

- Sewer and water pipes

- Valves and seals

- Couplings

- Medical equipment

- Essential parts in the energy grid

- Compressors

#2 Cost-effective Production of Complex Parts

Generally speaking, metal casting is the most cost-effective technology for producing complex parts. According to a recent study, when OEMs turn a welded and a machined part to single casting, they can generate up to 50% savings. That is, savings in both production time and production costs.

Some of the best and most experienced foundries can even cast walls that are as thin as eighth of an inch.

#3 Wide Suitability

Metal casting is a production process with zero restrictions in terms of thickness, size, and shape. Additionally, there is no restriction in terms of quantity. Even the most sophisticated engines, cylinders, impellers, valves, and other parts can be easily manufactured in large numbers and top quality.

#4 Metal Casting is $33.1 billion industry (in the US)

The US metal casting industry produces 90% castings of all manufacturing machinery and other durable goods. It is an industry whose payroll goes over $8 billion annually. Most of the companies in this industry are small businesses (75%) that employ 100 workers or less.

#5 Availability of Materials

Every material that can be used for metal casting is widely available. Some of the most common materials used for metal casting are steel, platinum alloy, stainless steel, various aluminum alloys, copper alloy, iron alloy, and others. Thanks to that, it is much easier for small startups to create their prototypes quickly. This also gives metal casting an edge over metal 3D printing, which is still in its early days.

In Conclusion

Metal casting is one of those “little things” that somehow manage to go under the radar of mass media. But their importance cannot be denied as it means a great deal to the economy, as well as modern society in general. It’s inevitable that even amid the current pandemic, metal casting will play a big part in how we re-build our world.