With the rise in awareness about the environment pollution and the declining ecosystem, in the recent years, there has been a rise in renewable fuels. Renewable sources of energy are the sources that won’t get depleted over repeated use. One of the most popular source of fuel is Biomass that’s obtained from biomass processing equipment. Biomass is the total quantity of mass of any biological component present in the ecosystem.

This includes plants, animals and even humans. These biomass, especially waste products from the industrial plants that are originated from trees can be recycled, processed and create energy that can help the future generation. Not only that, biomass processing is very important step when it comes to recycling in general. Several types of plant based waste products can be recycled with the help biomass processing. In this article, details about biomass processing has been discussed.

Biomass Processing Stages

Biomass processing has several stages that are required to be fulfilled in order to have it fully processed.

1. Fuel Reception & Weighting

Just like every equipment, biomass processing requires several of them. One of them being the fuel reception equipment. This equipment receives the fuel that is necessary for biomass to processed. The other is weighting. As biomass is usually supplied to processing units in bulk, it is absolutely necessary to make sure you don’t accidentally overload your processor.

2. Preparation & Drying

The next step for biomass processing is preparing the biomass to be processed. That includes cleaning it, ensuring there’s no director gunk that might contaminate the entire batch. Then there is a drying machine that is used to dry the biomass.

3. Separation

After drying it, the biomass is put through a machine that separates it. It can be based on size, weight and other variable dimensions. This is done to make sure there is an uniformity in the result after the processing is done completely.

4. Crushing & Chipping

After being processed and separated, the next step requires the biomass to be crushed and chipped. This is done to increase the surface area and also to make it much easier to do a screening on. This also helps in the future when biomass is fed into the storage feeders and sorted. Anything that doesn’t fit immediately can be weeded out with ease.

5. Screening

Screening is an important step in biomass processing. This is done to weed out any anomaly just like crushing and chipping. Except, when it comes to screening, the weeding out process is much simpler, owning to the smaller size of masses due to the previous step.

6. Storage Feeders

Storage feeders are are a combination of storage hoppers and vibratory feeders. Storage hoppers are places that store bulk amount of solid in them for future use. Vibratory feeders are feeders with a bowls that is used to give individual items to the assembly lines. Storage feeders combine the work of both and do it quicker.

7. Sorting

Sorting equipment is used to separate the different sizes of biomass that has been processed. These sorted bunch of biomass is then packaged and supplied to different industries. It helps wen the biomass processed comes out in dried out pellet form. These pellets are light weight, easy to carry, easy to sort, and easy to package.

Conclusion

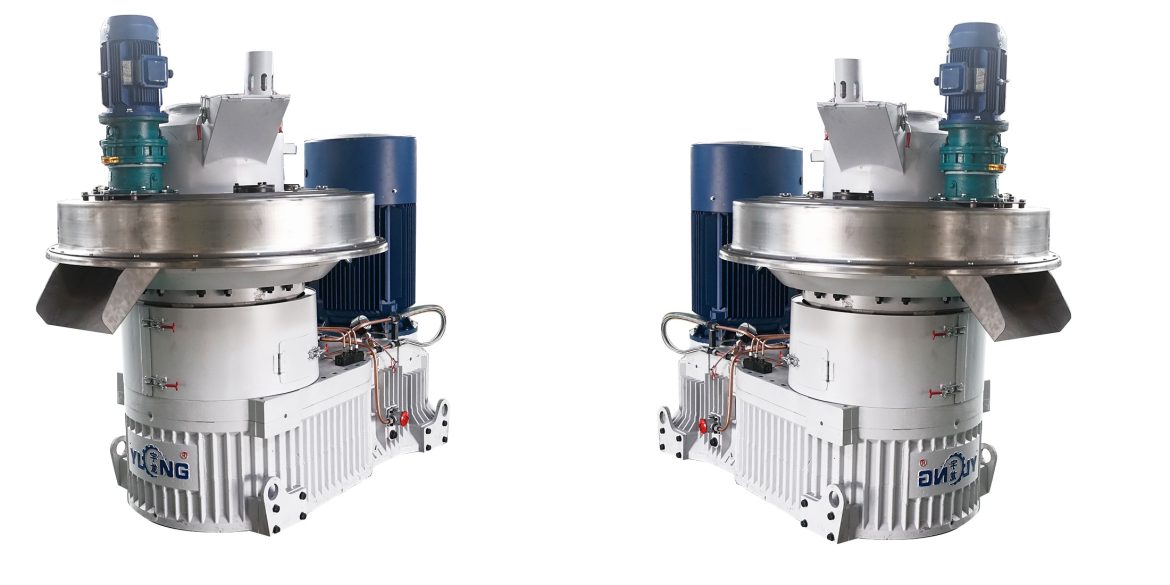

Yulong has introduced one of the most heavy duty biomass processing unit in the market. With its high capacity and high production rate, these machines produce about 3 ton of processed biomass in pellet form for easy packaging. These machines are made of stainless steel that make them perfect for long term use. They have different machines that form pellets with varying level of moisture for easy use.