When the possibility of 3D printing is known throughout even more sectors, 2020 is established to be the year. We’ve seen in the previous decade how 3D technology has transformed traditional manufacturing models as well as process on their head, providing on-demand, custom manufacturing– and also offering us with a contemporary version of the artisan age. This is just mosting likely to create even more as we begin this new decade.

What are the essential trends to view out for, and also where will we see the 3D market focus its attention in 2020?

Automation will thrive on the factory floor

Automated assembly is mosting likely to arrive, with industries effortlessly integrating multi-part assemblies– including combinations of 3D published steel and also plastic parts. Factors such as refining temperature levels suggest that presently there is no ‘extremely printer’ that can do all things fundamentally, like print steel and also plastic parts alike. Enhancements in automation mean we will see more synchronized manufacturing.

Take the automotive market as a possible example. Manufacturers will certainly can adding (i.e. printing) metal components to plastic components, build parts that are wear-resistant, add surface area therapies and also construct electric conductors or electric motors into plastic parts. Whilst the market isn’t all set to bring this modern technology to market right now, it’s an example of exactly how computerized setting up will shape 3D printing in the 2020s.

Lasting manufacturing will certainly be increased

3D printing as well as digital production is driving a world with less waste, much less inventory as well as reduced CO2 emissions. Given that nearly one-third of the latter comes from production, this can have an extensive impact on the planet.

Designers and engineers alike will certainly reconsider style throughout the item lifecycle to reduce waste. New materials and also complex geometries can generate lighter components, providing knock-on advantages – such as fuel performances for the automobile industries.

3D printing has already transformed manufacturing on its head, with technologies helping companies move from style as well as prototypes to product in under a week. Supply chain disturbances will increasingly become a distant memory, as production of parts can be done flexibly and also on location. As more suppliers select to transmit electronic apply for manufacturing in your area – as opposed to delivering items– you will see significant decreases in delivery, which in turn will minimize expenses, waste, and also discharges.

Data payloads for 3D printed parts

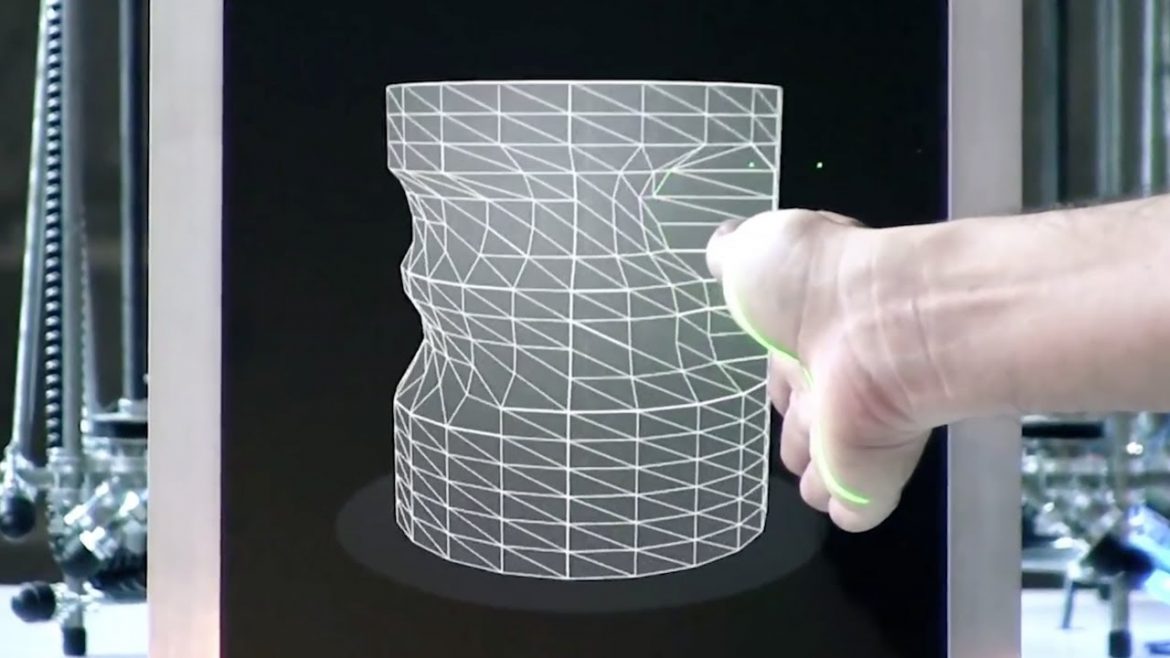

Making use of innovative 3D printing, organisations will certainly have the ability to code digital information right into the surface appearance itself offering makers a larger data haul than a typical serial number.

Via this application, organisations can tag a part overtly or discreetly, for either equipments or people to check out– such as through shape as well as positioning of bumps. This will tie 3D printing technologies to the future of components as well as product monitoring, an industry by itself.

Customer wellness & electrical automobiles will drive 3D development

Applications in footwear, eyeglasses and orthodontics are confirming financially rewarding for the 3D market. The customisation choices offered by 3D printing innovations includes value to these markets– whether it be customized shoes, braces or sunglasses that are customised to the user. SmileDirectClub– which released in the UK in 2015– is already electronically transforming the $12bn orthodontics sector. This growth in mass customisation will just continue as even more companies make use of the advantages on offer.

The 2020s will certainly be defined by auto producers seriously moving right into the electric vehicle market. The fast prototyping as well as manufacturing capacities of 3D permits makers to create cars and truck components at a speed previously impossible to develop. This must assist drive down prices which, if handed down to the client, will help get rid of one of the major obstacles to mass e-vehicle uptake.

Need for students that ‘assume in 3D’

3D printing’s greatest effect on making job skills lies on the style side. You have a world of developers who have been learnt and also grown up with existing technologies like injection moulding. People unintentionally predisposition their design towards legacy processes and also away from modern technologies like 3D printing since of this.

Colleges and also training programs will build a brand-new collection of believed procedures to liberate designers from old thinking and allow them to take advantage of 3D printing. As educators embrace new software application design devices and also advertise additive manufacturing education and learning programs, pupils will certainly be much better furnished to make use of the countless work that the 3D printing industry will certainly create in the following decade. In the UK, we’ve seen actual progress on this already, with the likes of CREATE Education introducing 3D printing institution hubs in recent months.

Inevitably, there are couple of various other modern technologies with this much potential to fundamentally alter every aspect of just how the globe layouts as well as makes. The next year, and the decade as a whole, is readied to be an interesting one for 3D print.