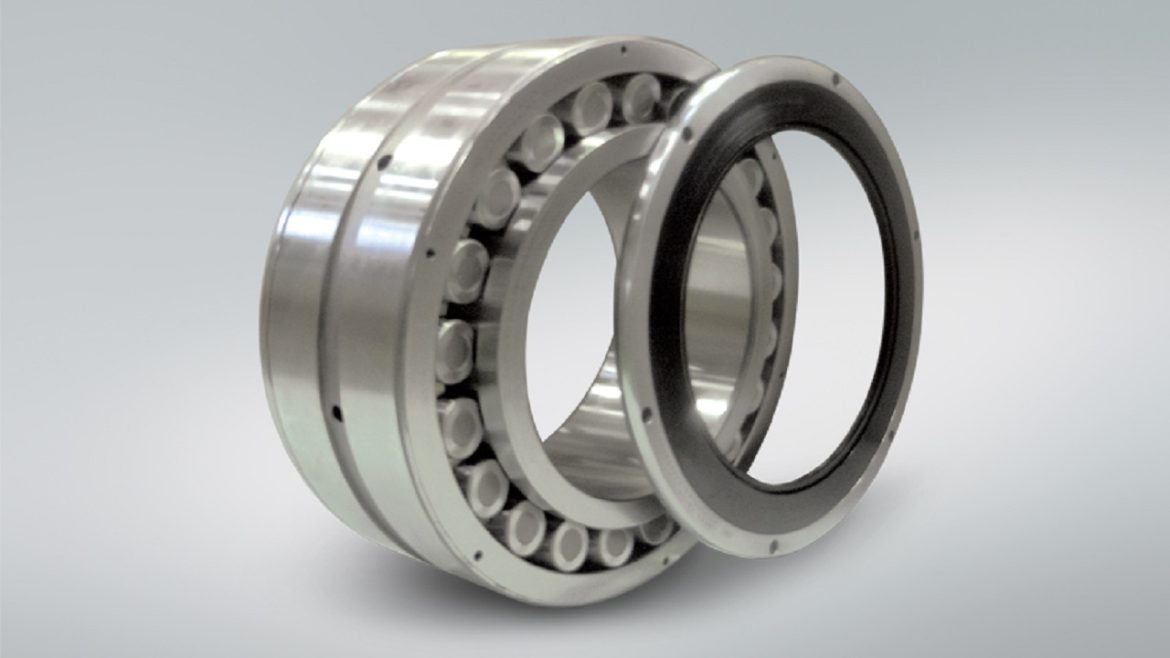

Ball bearings’ durability and performance are frequently dependent on the level of protection they receive. Ball bearings need seals and shields to protect them from impurities, reduce friction, and increase their operational life. In this article, we will explore the importance of seals and shields for ball bearings and guide you through the process of choosing the right protection for your specific needs, including those offered by aubearing roller bearings. Let’s first look at the role of seals and shields.

The Role of Seals and Shields

Let’s first comprehend the fundamental functions that seals and shields perform in ball bearings before moving on to the selection process:

Lubricant Retention

Lubrication is necessary for ball bearings to reduce heat production and friction. Seals and shields aid in keeping the lubricant inside the bearing, ensuring that the rolling elements continue to receive the best possible lubrication.

Reducing Friction

Shields and seals both lessen friction but to different degrees. The efficiency and speed of the bearing’s operation may be affected by the decision between the two.

Let’s now examine the choices that are available and how to make the best decision.

Shields for Ball Bearings

Shields, also known as metal shields, offer a different approach to bearing protection. They are typically made of metal and do not make direct contact with the inner ring. Shields are available in two main types:

Single Metal Shield (Z)

A single metal shield, designated as Z, provides moderate protection against contaminants while offering relatively low friction. It’s suitable for applications where some exposure to the environment is acceptable, and low friction is essential.

Double Metal Shield (ZZ)

Double metal shields, labeled as ZZ, offer enhanced protection compared to single shields. They create a robust barrier against contaminants, making them suitable for applications where cleanliness is crucial. However, they may generate slightly more friction than single shields.

Seals for Ball Bearings

Seals are designed to provide a high level of protection for ball bearings. They come in two primary types:

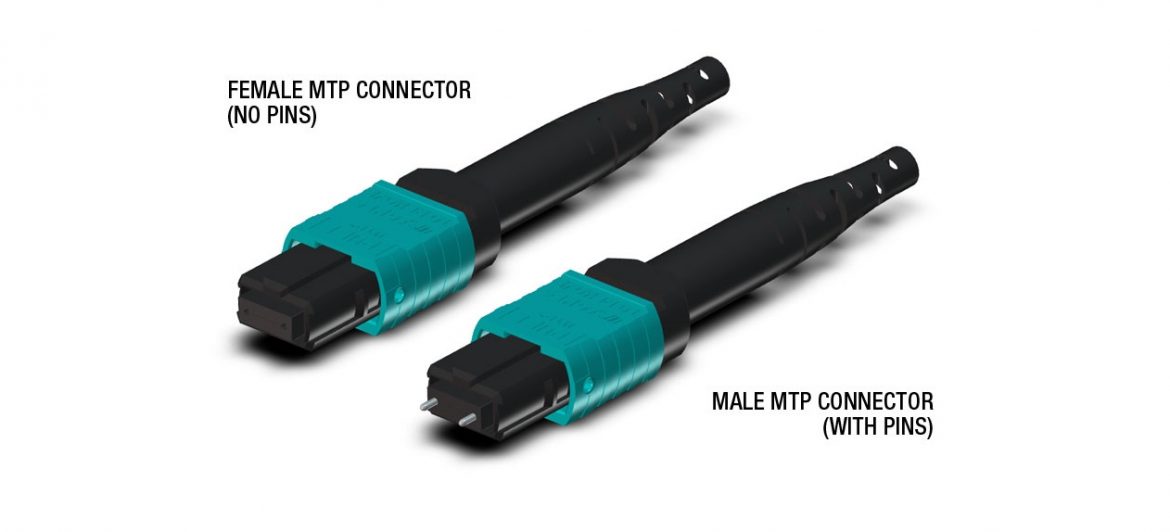

Contact Seals (RS or 2RS)

Contact seals, often designated as RS or 2RS, create a physical barrier between the bearing’s interior and the external environment. They make direct contact with the inner ring of the bearing, providing a highly effective seal against contaminants. However, contact seals can generate slightly more friction compared to shields due to their direct contact with the inner ring.

Non-Contact Seals (RZ or 2RZ)

Non-contact seals, denoted as RZ or 2RZ, offer protection without making direct contact with the inner ring. They provide a lower level of friction compared to contact seals, which can be advantageous for high-speed applications. While they are effective at keeping contaminants out, they may not be as robust as contact seals in extreme conditions.

Choosing the Right Protection

Selecting the appropriate protection for your ball bearings depends on your specific application requirements. Here are some factors to consider:

Environment

Assess the operating environment for your ball bearings. If it’s a clean and controlled environment, shields may suffice. In contrast, harsh or dirty environments may demand contact seals for optimal protection.

Lubrication

Ensure that your chosen sealing or shielding method is compatible with the lubrication used in your bearings. Lubricant compatibility is crucial for maintaining smooth operation.

Conclusion

In conclusion, selecting the right protection in the form of seals and shields is a critical decision when it comes to ball bearings. It impacts the bearing’s performance, lifespan, and efficiency. By carefully assessing your application’s requirements, environmental conditions, and speed considerations, you can make an informed choice that ensures the longevity and reliability of your ball bearings. And when you choose aubearing roller bearings, you’re opting for quality and precision in every aspect of bearing technology.