Every industry runs on parts. A too large or too small must have bits to suit it. The system may falter on the breakdown of one section. That is why manufacturing custom parts is so important in the industrial context. This is where Kaierwo comes in. With CNC Machining Services, they help different industries get the parts they need—fast, correct, and ready to work.

Made to Fit the Job

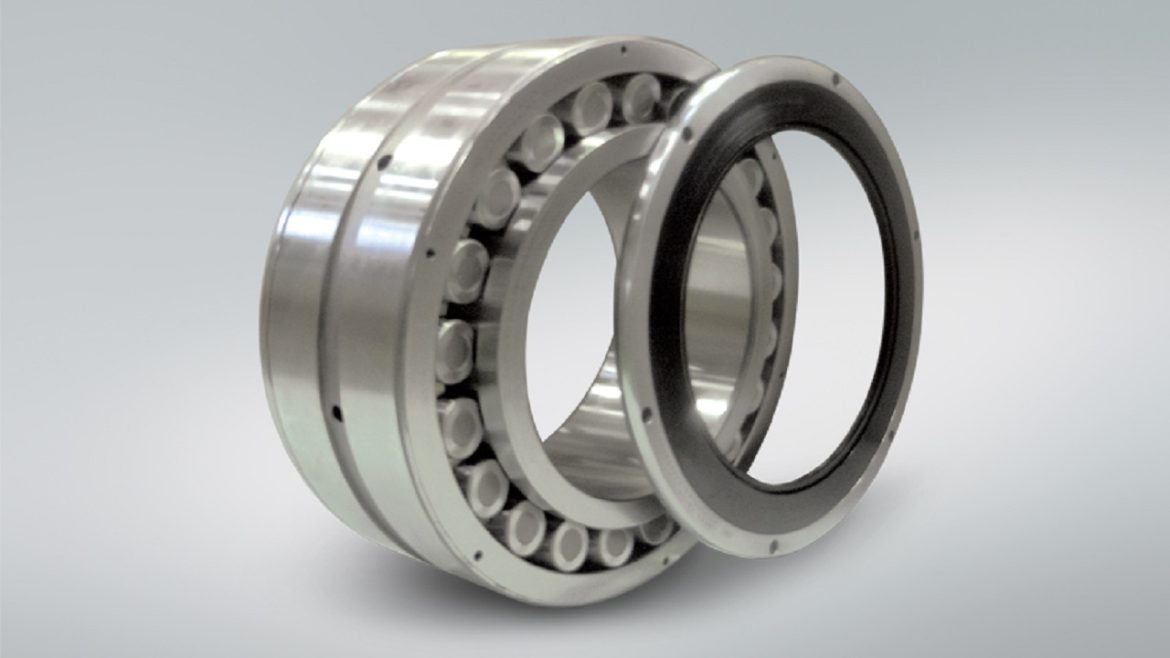

Some machines can’t use parts off the shelf. They need something designed for a single purpose. Kaierwo makes that happen. With CNC machining, every cut follows a plan. It’s not guessing. It’s not one-size-fits-all. It’s custom. Machines that are used in factories, farms, builders, and labs require special parts. These sections can be of fat or thin, round or square, big or small. Whatever their form, they must be correct. Kaierwo can take a drawing and turn it into a real, working part that fits exactly.

Fast and Steady Work

Time matters in business. When a machine breaks, work stops. That costs money. Getting the right part fast can fix that. Kaierwo knows how to keep work moving. Once the order comes in, the machines get going. The cutting begins, and the parts emerge clean. Even when the job is big, the process stays smooth. Each piece is checked. Nothing is rushed. But it doesn’t drag on either. That mix of speed and care helps people get what they need on time, with no surprises.

Built to Last

In a factory, parts get pushed hard. They take hits, hold weight, or move all day. Weak parts won’t last. That’s why the quality matters. Kaierwo utilizes high-quality metal and advanced machines. They cut and shape every part to withstand stress. Some jobs need soft touches. Others need raw strength. Kaierwo selects the right approach to make each part stand up to its task. That means fewer breakdowns and longer life for the machines that use them.

Many Industries, One Method

From car plants to farming tools, from laboratories to heavy trucks, many industries rely on CNC parts. Kaierwo works across all these areas. Each client has a unique need, but the process remains the same: listen, plan, cut, check, and deliver. The tools and machines used may change, but the focus on clean, careful work doesn’t. That’s what makes the parts valuable. It’s not about big words or complex gear. It’s about making things that just work, day after day.

People Come Back for a Reason

When a part fits right the first time, people remember. When it appears quickly and lasts a long time, it comes back. That’s how Kaierwo has kept going strong. Not by chasing buzz or showing off. Just by doing solid work, that gets noticed. Many clients start with one job. They test the work. Then they stay. That trust doesn’t come from ads. It comes from parts that don’t fail and machines that don’t stop.

Conclusion

Custom parts keep industries moving. They hold things together, make things run, and fix what’s broken. Kaierwo helps do all that through CNC machining. Each piece is made with care. Every job gets the attention it needs. In the end, it’s not about showing off. It’s about simple, clear work that gets real results. And that’s what keeps Kaierwo in the picture—one clean cut at a time.